JC624-05 Industrial Liquid Pressure Transducer Overview:

JC624-05 industrial liquid pressure transducer is a civil and industrial product with large consumption and low costs, for which a new standard of cost performance has been established. This series of products is widely used for pneumatic and hydraulic detection even in very harsh medium environment such as sewage, vapor, slight corrosive liquid and gas.

JC624-05 series is designed with foreign advanced micro-machined silicon pressure-sensitive resistance metal membranes. Micro-melting technology is adopted to solidify the high-temperature glass on the stainless steel isolating membrane. Glass cementation avoids the influence of temperature, humidity, mechanical fatigue and medium on the adhesive and material, thus enhancing long-term stability of the sensor in industrial environment. Meanwhile, the effect of P - N junction in a conventional micromechanical sensor can also be avoided.

JC624-05 Industrial Liquid Pressure Transducer Features:

* Leakage protection

* Low-cost OEM

* Free of O-ring, silicone oil, and welding seam

* Millivolt or standard signal output

* High cost performance

* Wide range of operating temperature

* Single-piece integrated structure made of stainless steel

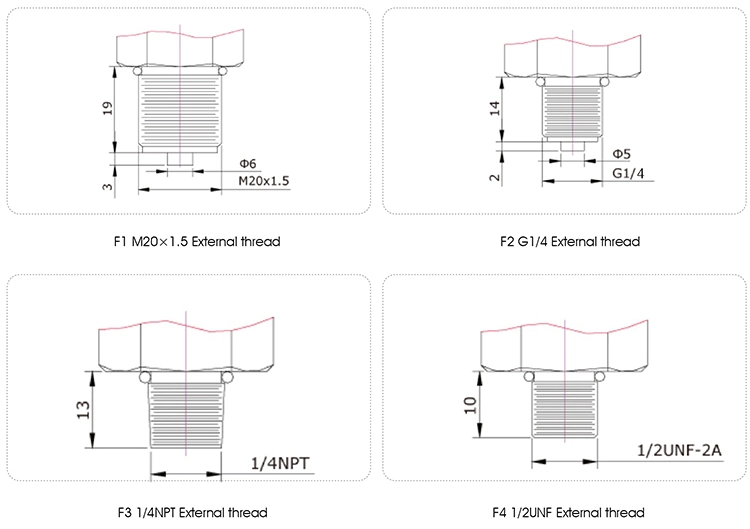

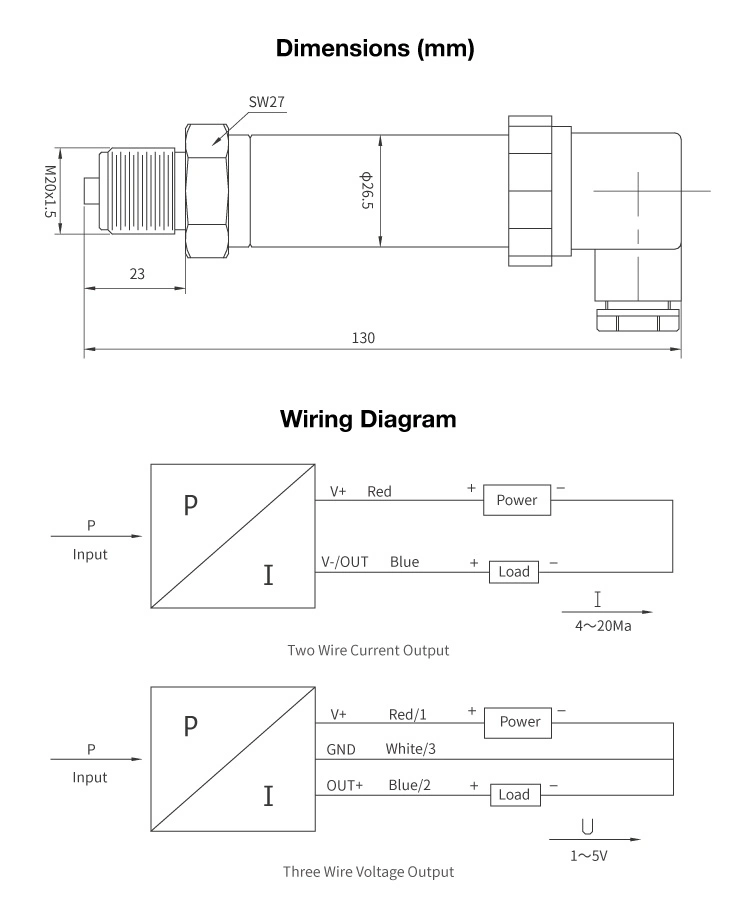

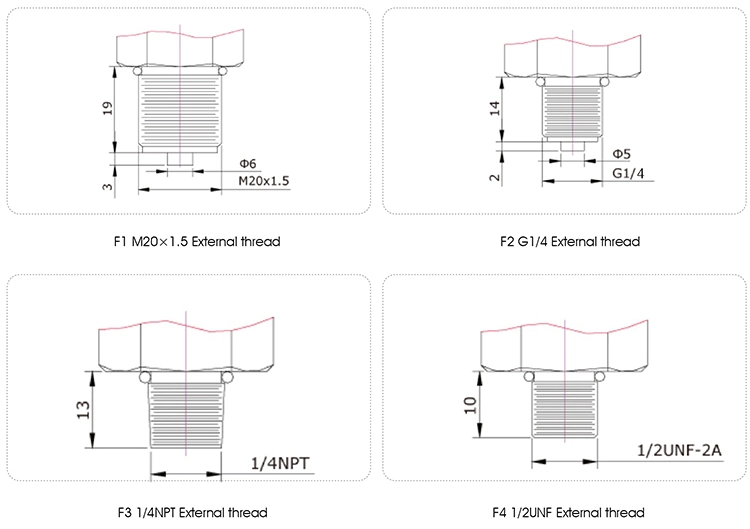

Process Connection Drawings:

JC624-05 Industrial Liquid Pressure Transducer Application:

* Pump and compressor

* Hydraulic and pneumatic system

* Energy and water treatment system

* Automatic detection system

* Agricultural equipment

* Refrigeration equipment --- Freon or ammonia

Technical Parameters:

certification

trade show

packing and shipping

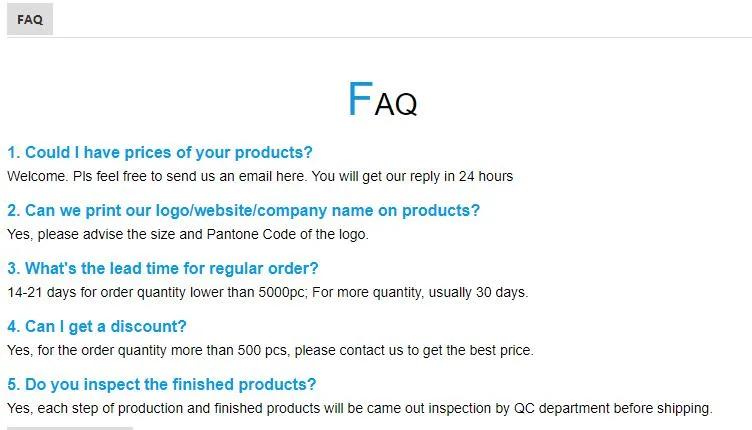

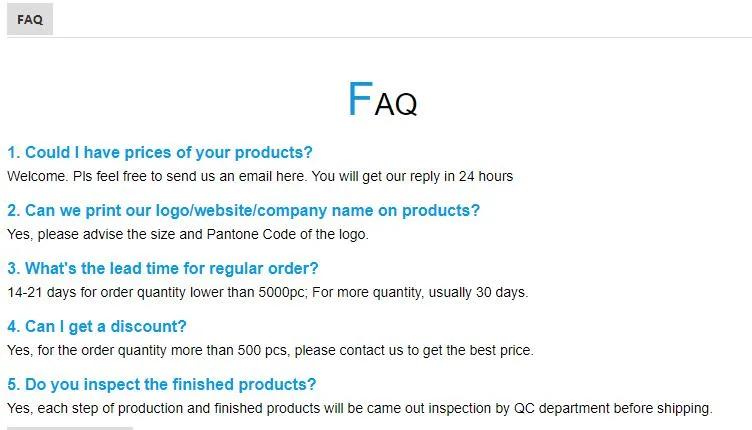

FAQ

JC624-05 industrial liquid pressure transducer is a civil and industrial product with large consumption and low costs, for which a new standard of cost performance has been established. This series of products is widely used for pneumatic and hydraulic detection even in very harsh medium environment such as sewage, vapor, slight corrosive liquid and gas.

JC624-05 series is designed with foreign advanced micro-machined silicon pressure-sensitive resistance metal membranes. Micro-melting technology is adopted to solidify the high-temperature glass on the stainless steel isolating membrane. Glass cementation avoids the influence of temperature, humidity, mechanical fatigue and medium on the adhesive and material, thus enhancing long-term stability of the sensor in industrial environment. Meanwhile, the effect of P - N junction in a conventional micromechanical sensor can also be avoided.

JC624-05 Industrial Liquid Pressure Transducer Features:

* Leakage protection

* Low-cost OEM

* Free of O-ring, silicone oil, and welding seam

* Millivolt or standard signal output

* High cost performance

* Wide range of operating temperature

* Single-piece integrated structure made of stainless steel

Process Connection Drawings:

JC624-05 Industrial Liquid Pressure Transducer Application:

* Pump and compressor

* Hydraulic and pneumatic system

* Energy and water treatment system

* Automatic detection system

* Agricultural equipment

* Refrigeration equipment --- Freon or ammonia

Technical Parameters:

| Measuring range | 0~100KPa...70MPa | |||

| Pressure type | Gauge pressure or absolute pressure | |||

| Permissible overpressure | Two times of full-scale pressure | |||

| Measuring media | The gas or liquid compatible with 316 stainless steel | |||

| Power supply | 5V DC | 12~36 VDC (generally 24V DC) | ||

| Signal output | ≥70mV DC | 4-20mA, 1-5 V, 0~5 V, 0.5-4.5 V | ||

| Accuracy(nonlinearity + hysteresis + repeatability) | ±0.5%FS(typical value) | |||

| Long-term stability | ±0.25%FS/year | |||

| Range of operating temperature | -20~+85ºC | |||

| Range of compensation temperature | -10~+50ºC | |||

| Temperature performance | Zero temperature coefficient: ±0.04%FS/ºC(typical); ±0.06%FS/ºC(maximum) | |||

| Sensitivity temperature coefficient: ±0.04%FS/ºC(typical); ±0.06%FS/ºC(maximum) | ||||

| Thermal hysteresis | ±0.1%FS(typical) | |||

| Electrical connection | PG7cable connection | Connector DIN43650 | ||

| Enclosure protection class | IP67(cable type) | IP65(socket type) | ||

| Response time(10%~90%) | ≤3ms | |||

| Load resistance | ≤(U-12)/0.02 Ω | |||

| Insulation resistance | 100MΩ, 500VDC | |||

| Safety and explosion protection | Ex ia II CT6 | |||

| Vibration error | ≤±0.01%FS(Axes X, Y, Z, 200Hz/g) | |||

| Weight | Approx. 250g | |||

certification

trade show

packing and shipping

FAQ